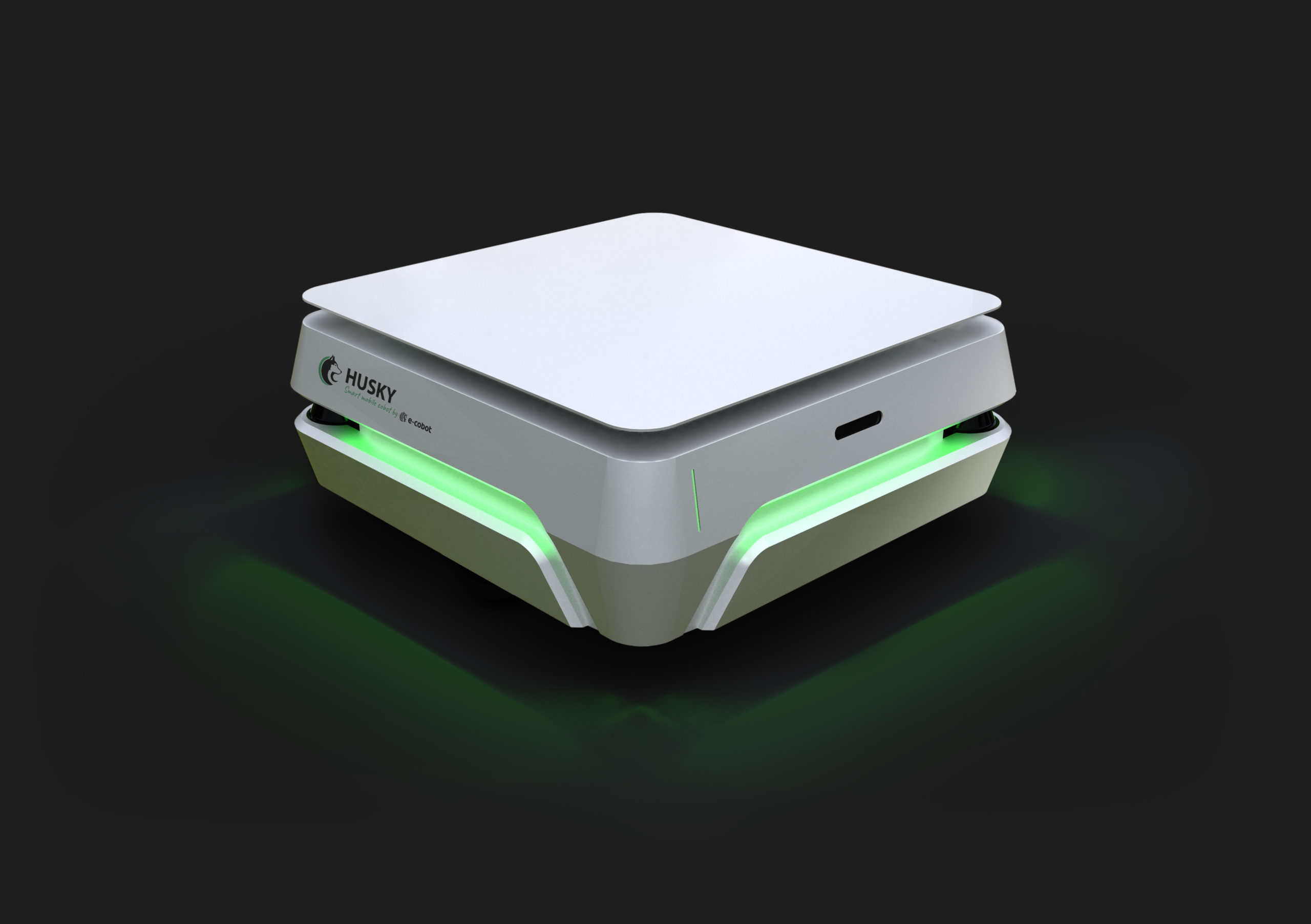

HUSKY

SMART MOBILE ROBOT

Carries up to

250 kg

Tows up to

1 tonne

battery life

10 hr

safety vision

360°

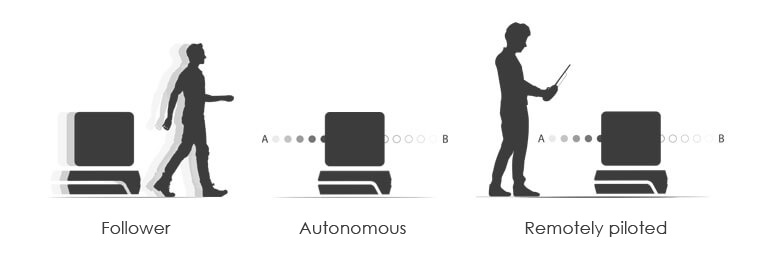

3 OPERATING MODES

DESIGNED TO COLLABORATE

HUSKY is a SMART MOBILE COBOT,meaning that it can perform tasks in collaboration with a person thanks to its embedded intelligence. It is designed to be an extension of the human body to optimise everyday movements as effectively as possible.

HUSKY delivers two benefits: reduce MSD caused by handling rolling or carrying devices and perform all of the lengthy trips in your store in order to focus People’s capacities on high value-added tasks. It is estimated that HUSKY covers nearly 2,000 miles every year, the equivalent of a Paris to Lisbon round trip.

BEHAVIOUR

JUST AS YOU’D EXPECT :

RELIABLE, INTUITIVE AND FLEXIBLE

All of the HUSKY models in our range are equipped with cutting-edge localisation and navigation technologies. Its algorithm is unique and has already been proven over more than 58,000 hours based on test protocols from the automotive industry (58,000 hours is equivalent to 6.6 years). It is also continually evolving to bring you the best performances and enhance its capabilities over time.

Forget what you might have heard elsewhere: the notion of precision doesn’t exist and the use of this term is not applicable when talking about metrological information. We prefer to talk about positioning accuracy and repeatability. In terms of performances, HUSKY is accurate to +/- 15 mm and has a repeatability of +/- 1.5 cm. These performances are possible thanks to the SLAM* through a combination of various technologies:

-

- Inertial navigation units

- Navigation laser

- Dual-channel encoders on each wheel

(safe speed management and robustness of the data from the laser scanners). - Odometry

*SLAM stands for simultaneous localisation and mapping. The AMR SLAM can map the environment and locate itself on this map

HUSKY’s navigation functions have been designed to give you complete confidence in its ability to deliver to the requested point, naturally.

Natural navigation is without a doubt the technological advancement you’ve been waiting for: HUSKY can move in any indoor or covered outdoor environment without you needing to position markers, magnetic wires or a reflector.

The HUSKY mobile robot safely navigates in your premises, staying on track until the very end even if there are periodic network failures. Its 3D camera detects obstacles 2 metres ahead (from 5 cm to 80 cm high), while its laser scanner detects stationary and moving obstacles up to 25 m away. Our navigation system is continually evolving towards real-time visual navigation: with E-COBOT the future is within reach.

- Localisation

-

Forget what you might have heard elsewhere: the notion of precision doesn’t exist and the use of this term is not applicable when talking about metrological information. We prefer to talk about positioning accuracy and repeatability. In terms of performances, HUSKY is accurate to +/- 15 mm and has a repeatability of +/- 1.5 cm. These performances are possible thanks to the SLAM* through a combination of various technologies:

-

- Inertial navigation units

- Navigation laser

- Dual-channel encoders on each wheel

(safe speed management and robustness of the data from the laser scanners). - Odometry

*SLAM stands for simultaneous localisation and mapping. The AMR SLAM can map the environment and locate itself on this map

- Navigation

-

HUSKY’s navigation functions have been designed to give you complete confidence in its ability to deliver to the requested point, naturally.

Natural navigation is without a doubt the technological advancement you’ve been waiting for: HUSKY can move in any indoor or covered outdoor environment without you needing to position markers, magnetic wires or a reflector.

The HUSKY mobile robot safely navigates in your premises, staying on track until the very end even if there are periodic network failures. Its 3D camera detects obstacles 2 metres ahead (from 5 cm to 80 cm high), while its laser scanner detects stationary and moving obstacles up to 25 m away. Our navigation system is continually evolving towards real-time visual navigation: with E-COBOT the future is within reach.

SAFETY

OUR PRIORITY

The design of our products is centred around safety. Our risk analyses have been validated by specialised supervisory firms and we incorporate ten physical safety features, including a UN38.3 certified battery. We work with experts to resolve any cyber security risk and strictly meet the ISO 3691-4 standard, which governs requirements and verifications for driverless industrial trucks and their systems. There’s no need to be concerned about remote access points: our AXEL BOX is ISO 27001 certified.

HUSKY guarantees the safety of goods and individuals thanks to safety scanners controlled independently of the navigation by three safety PLCs. This is used to generate horizontal immaterial zones around the robot that change according to its speed. It maintains a minimum safe distance irrespective of its speed.

As an option, scanners can be combined with HUSKY safety PLCs, which enable you to add a vertical or ground-facing layer warning of any non-detectable obstacles on a single plane.

Including in our products a UN-38.3 certified battery that can last for 16 hours during full use is essential. This certification is a mark of quality and enables its transportation (by truck, boat and plane both in France and abroad). It also provides peace of mind regarding the use of such a powerful lithium battery.

Once installed, HUSKY becomes a strategic element of your production or logistics process, as it incorporates your sensitive data.

This is why E-COBOT works with cybersecurity experts on:

- The analysis of risks and operational safety

- The cobot’s authentication, identity and footprint

- The protection of the data involved in the cobot

CONNECTIVITY

REAL-TIME DATA EXCHANGES FOR SIMPLICITY

The connection between HUSKY, its peripherals and third-party computer systems is unparalleled in its simplicity. We incorporate IoT technologies from 2021 to make our global solution ultra-accessible to use and ultra-connected.

HUSKY can operate alone without a wireless network; thanks to its API it can receive information from a third-party system to launch its mission (sensor concentrator, third-party PLCs, MyCobot USER, MyCobot MANAGER, Customer IS). HUSKY can even control PLCs, sensors, door openers and lifts.

The interface (API) can process controls for retrieving the data inherent to HUSKY in order to provide input for your indicator in Mycobot MANAGER or your IT system.

Remote software updates via AXEL BOX bring you new features and improve HUSKY’s performances. This also allows for instantaneous maintenance work.

FLEET MANAGEMENT

A PACK OF HUSKIES

SERVING YOU

Combining several HUSKY units is one of E-COBOT’s strengths, enabling each mobile robot to use its individual intelligence (Mycobot OS) to serve the group on collaborative assignments. Our fleet management system (MyCobot MANAGER) enables 100 HUSKY units to be controlled in a single environment.

The interfaces of the MyCobot USER and MyCobot MANAGER software suite help you oversee, manage and configure products, maps, assignments and access rights, as well as view the locations of mobile robots and monitor flows, traffic and assignment requests. You can also monitor the status and performance indicators of the fleet and be notified by SMS or email if obstacles are preventing the robots from completing the scheduled tasks.

The interfaces of the MyCobot USER and MyCobot MANAGER software suite help you oversee, manage and configure products, maps, assignments and access rights, as well as view the locations of mobile robots and monitor flows, traffic and assignment requests. You can also monitor the status and performance indicators of the fleet and be notified by SMS or email if obstacles are preventing the robots from completing the scheduled tasks.

FMS allows you to manage the traffic rules and priorities in relation to other mobile machinery. It establishes a hierarchy and automatically selects the robot best suited to a task, based on its position and its availability to handle the requested assignments. It backs up and stores the fleet’s data (robots, accessories, maps and assignments).

The FMS also reduces modifications to your ERP or WMS system by automating the robot’s tasks. It brings autonomy to your facility, as it shows the location and status of the robot in real time, places a priority on important jobs and optimises task allocation.

TECHNICAL FEATURES

Dimensions :

750 x 750 x 350 mm

Weight:

64 kg

CE battery

Running time:

10 hrs

Nominal speed:

3.7 mph

Slopes :

10%

Carried payload:

250 kg

Towing capacity:

1,000 kg

Towing capacity by indexing

(underneath the load):

500 kg

Adjustable safety fields