Industry

Industry and cobotics: a key differentiation factor for increasing the productivity and flexibility of europe’s manufacturing industry

ISSUES :

– Numerous round trips between workstations

– Logistics units are numerous, heavy and difficult to move

– One person is in charge of moving empty containers

– One person is dedicated to supplying or clearing logistics units

CHALLENGES :

– Eliminate unnecessary trips by optimising working time

– Improve productivity

– Make flows more fluid and adapt to product processes/paces (supply and clearing)

– Improve staff working conditions

Industry and cobots: the background

The technology of cobots and collaborative robots has become the backbone of many large-scale manufacturing industries. To compete globally, manufacturing needs to be both competitive and agile. Cobots are the main drivers of flexibility and competitiveness and will help to bring manufacturing back to Europe.

As automation pressure overtakes traditional manufacturing industries such as automotives and electronics, the need for flexibility in these automation systems is growing, particularly for SME manufacturers. Meeting these needs will require new technologies and new working practices.

As Europe strives to increase the manufacturing sector’s added value, it will be competing not only with low-pay economies but also highly automated economies.

The market opportunities in industry

The current market for robotics technology in manufacturing is focused on large-scale manufacturing industries, which have high levels of automation. However, it is widely recognised that the impact of robotics technology on manufacturing needs to broaden its base to encompass a wider range of manufacturing, particularly among SMEs.

Increasing the flexibility of industrial robots and supplying automation systems that provide more intuitive and faster configuration are important goals for future production systems.

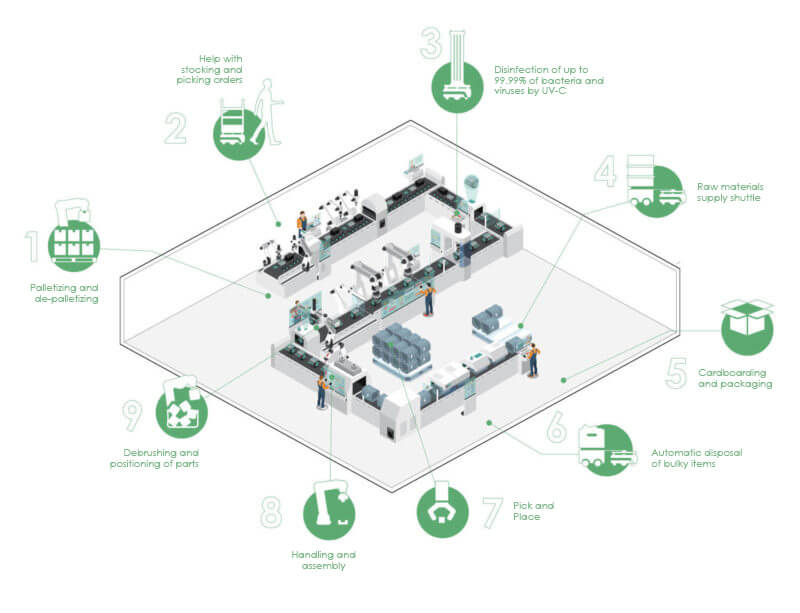

Learn about the use cases of our cobotics solutions for industry

Palletisation and depalletisation

Increase your palletisation rate

I have to divide up boxes on pallets for different destinations. A collaborative robot helps me position the boxes on the pallet. I operate several palletisation workstations and make sure the pallet is stable before the forklift truck operators handle them.

Support with addition to

inventory and order picking

Improve the effectiveness of addition to inventory and picking/kitting

I have to prepare kits of parts or subassemblies for the assembly lines. In follower mode, HUSKY follows me on all my trips and I have both hands free to concentrate on the items to pick. I can also use HUSKY for adding to inventory.

Up to 99.99% disinfection of

bacteria and viruses by UV-C

Ensure the health and safety

of staff and customers

Because my department handles enclosed members of the public, my last teams leave the premises and I initiate a scenario for disinfecting all visible surfaces by UV-C to kill up to 99.99% of bacteria and viruses in just one hour over an area of 450 m².

Autonomous shuttle for raw materials

Increase your production

capacity at workstations

I need a raw material, parts or subassemblies at my workstation, HUSKY handles autonomous rounds and supplies me regularly. I concentrate on my production station and eliminate low value-added trips.

Boxing and packing

Increase your packing rate.

I check plants at the end of the production line. A collaborative robot helps me take the validated parts and place them in their boxes before shipping. I stay fully concentrated on the quality of products.

Automatic clearing of bulky materials

Increase your available space on the floor and productivity at the workstation

My production machine generates surplus materials, waste, etc. HUSKY performs autonomous rounds and clears the waste skips and empty pallets. I concentrate on my production station and eliminate low value-added trips.

Pick and place

Increase your workstation supply rate

I’m responsible for product test benches. A collaborative robot helps me to unload the parts and supply the machine. I stay fully concentrated on the quality of products and additional visual checks.

Increase your production rate at workstations.

Increase your workstation supply rate

My products require sensitive manual assemblies that are difficult to access. A collaborative robot helps me to handle the part in the ideal position to make assembly easier.